We may receive a commission for products purchased through the links on our site at NO additional cost to you.

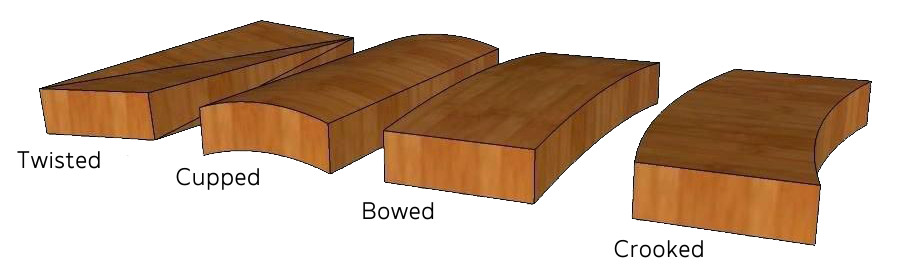

How many times have you been at the lumber store and came across a piece of wood that was not straight and had issues that would make it unusable for your project? Most people will say that this happened to them many times. Why is that? Lumber cannot always be perfect. This is where a woodworking jointer comes in. The best benchtop jointer can take that not so perfect wood and turn it into a piece that will work perfectly for your project. A wood jointer will straighten out the wood or work through the twists and bends that it may have. So how do you know what is the best jointer? Read our wood jointer reviews and guides to learn everything about power jointers.

Best Wood Jointer Reviews

[go_pricing id=”best_jointers”]Scroll down to see our exclusive features comparison chart, comparing power, dimensions, features, and more. In addition, to our top wood jointer reviews and buying guides.

1. Powermatic 1791317K 54HH Helical Cutter Head Jointer

An all steel closed stand jointer design, probably the best jointer for professional carpenters or serious home woodworkers. Uses a 1 horsepower motor and can run on both 115V/13A and 230V/6.5A.

It has a true helical cutter with carbide inserts arranged in spiral-shaped rows for effective and accurate performance. Operates quieter than conventional systems.

Has a cutting width of 6 inches and a cutting depth of 1/2 inch. The table is long to accommodate longer pieces of wood and adjustable to support smaller wood.

In addition, the cutter head is belt driven delivering maximum performance with an easy tension lever that rotates at 6000 RPM. The fence and cutter come pre-aligned and only require minor adjustments if any at all. The fence controls are center-mounted for extra convenience.

Pros:

- A helical cutter head with 40 knives spaced over 15 inches and placed at 14 degrees, achieving more accurate cuts resulting in an excellent shearing action.

- Integrated with 4 sided carbide inserts, each can be rotated four times. It also allows for replacing just one blade when needed rather than the entire cutter head.

- It has extra-long infeed and outfeed tables for a total length of 66 inches. Provides more working surface and support.

- The outfeed table is adjusted through a handwheel mounted below the table. To adjust the infeed table, the handle can be moved vertically. For finer height adjustments, the longer handle can be rotated. Mounted on dovetailed ways that keep it perfectly aligned.

- Two-way tilting fence that is 38 inches long with positive stops for 45, 90, and -45 degrees.

Cons:

- Weighs 328 pounds. It’s difficult to move it around your workspace.

- You might need a second hand to help you in the setup and mounting the jointer on the stand.

2. Cutech 40160HCT Benchtop Jointer

The Cutech 40160H-CT is an impressive affordable jointer. A 6-inch cutting width and 1/8 inch depth maximum cutting capacity. Features a spiral cutter head, similar to a helical cutter.

A 30-inch table and level adjustable beds, giving you enough space when working with long boards. An aluminum 20-inch fence with grooves which helps prevent the wood from sticking onto the surface.

Equipped with a spring-loaded guard to protect your fingers from contacting the cutting head, with an additional safety key next to the power button for emergencies. Features a 2 1/2 inch port option to hook up a dust collection unit or a shop vac.

This machine is ideal for limited home shop spaces and it’s actually the best jointer for home workshop. Weighs about 40 pounds, making it easy to transport and move around. It runs on a 120 volt 10 amp motor. Cutech truly takes into consideration what you are looking for rather than trying to push you into just any expensive model.

Pros:

- Although it is not an authentic helical cutter, it does a fantastic job in creating cuts that straighten the wood without leaving marks.

- It has 12 high-speed steel (HSS) double-sided blade inserts. Which allows you to rotate the blade to the other side when the main side is worn out.

- These spiral cutters operate significantly quieter than other machines.

- Packs a powerful motor with 11,000 RPM speed.

- A fence that can tilt anywhere from 90 degrees to 135 degrees.

Cons:

- The fence and the fence adjustment could be more sturdy.

- While it is lightweight, this could sacrifice some of its stability.

3. JET 708457DXK JJ-6CSDX Closed Stand Jointer

This is one of the top rated jointers for both novices and experienced woodworkers. It provides the most quality for the price of most machines on the market today.

An all enclosed base cabinet with mounting tabs to secure it to a stable floor surface for increased stability. It’s designed to last you for years with its heavy duty cast iron table, fence, knobs, and hand wheels.

Has a cutting width of 6 inches and a cutting depth of 1/2 inch. This long bed jointer features an extra-long table that is 56 inch for the infeed and outfeed giving you more control over the wood and best accuracy of the cut with a superior finish.

The fan cooled motor is 1 horsepower and runs on 115/230 volts 13 amps and it is very powerful. It can handle dense wood as hard as walnut or maple. Not to mention, the dust port is 4 inches which allow for a shop vac to be hooked up.

Pros:

- A 3 two-sided high-speed quick set knives system that allows you to easily change one or all three knives in no time. It holds the correct blade spacing without you having to spend time on calibrating.

- Everything lines up fairly well, the wood comes out nice and smooth with no chips.

- Provides a rapid speed of 6000 RPM.

- Has a 45 degrees two-way tilting fence with positive stops at 45 degrees and 90 degrees.

- A built-in 1/2 inch rabbeting ledges for extra versatility.

Cons:

- It’s really heavy. If you do not have someone to assist you, the assembly can take some time.

- When the machine is running and the wood is going through it makes a vibration, despite its weight. We advise stabilizing the stand before operating.

4. Porter Cable PC160JT Variable Speed Jointer

This jointer could possibly be the best benchtop jointer on the market and at a highly attractive price. Two steel knife cutter heads that can handle wood up to 6 inches in width with a 1/8 inches cutting depth. Thanks to the 110V/10A single phase 1.4 horsepower motor.

The table length is 30 inches and can straighten any board that is two times longer than the jointer itself. Very easy to use, the fencing is center mounted which makes it easier to get the wood at the right angle while trying to hold it correctly.

Weighs 35 pounds, a portable jointer which works great for contractors who do not do all their projects in one place. It would not require them to haul the wood to their workshop to correct it before then hauling it to the job site. In addition, it has a 4-inch dust port.

Pros:

- The cuts per minute is 12,000 to 22,000 CPM with a variable speed range of 6,000 to 11,000 RPM.

- The 5-speed setting allows you to adjust the speed according to the size and hardness of the wood while delivering superior results. Ideal for flattening, edging, and face jointing.

- A jackscrew knife leveling system and a cutter head lock, provides an easy knife adjustment without compromising your safety.

- A knob for raising and lowering the infeed table to change the cutting depth.

- The fence is 19.5 inches long with positive stops at 45 and 90 degrees.

Cons:

- Some would say that the arbor lock is weak. However, most woodworkers will not change the depth nor the fence settings very often. Therefore, the arbor lock will not be used that much.

- The tabletop is made of aluminum which makes it somewhat less durable.

5. Powermatic 1610086K 60HH 8-Inch Jointer

Built to handle a large volume of work for straightening the edges of a big load of lumber quickly and efficiently. A great choice when it comes to finding the best heavy duty jointer, combining accuracy and user-friendly features.

Has a cutting width of 8 inches and a cutting depth of up 1/2 an inch. Powered by a powerful 2 horsepower motor with 9 amps 230 volts.

A 54 cutting knives helical cutter head with 4-sided carbide inserts providing a smooth cutting experience combined with quiet operation and a superior finish.

Safety and convenience are also taken care of with high mounted operating switch and push blocks with a magnetic base that can be stored on the machine or any metal surface for easy access. Not to mention, the dust collection works great and leaves virtually no mess behind.

Pros:

- Gives you the option of using either four-sided helical cutter heads or three-sided knives depending on your requirements.

- Has a powerful motor that powers the 7000 RPM helical cutter head.

- Comes with extra long tables of 73 inches which gives you a lot of space to work with long lumber pieces. The tables are mounted on dovetailed ways, for adequate workpiece support.

- The infeed table lever offers quick table height positioning and for fine-tuning, the handle can also be rotated to achieve the exact cutting depth.

- Easy and accurate adjustment two-way tilting fence of 38 inches long with positive stops at 45, 90, and -45 degrees. A non-mar insert in the fence to protect the table from scratches during adjustments.

Cons:

- Very heavy, weighing 518 pounds. It is designed to stay in one place.

- The wood shavings exit from the front of the machine which can make a mess on your clothes.

6. Delta Power Tools 37-071 6-Inch Jointer

While other midi jointers are made from aluminum, the Delta has a durable cast iron construction which increases stability and reduces vibrations. Has two sharp knives. Operates on a 120 volt 12 amp, equipped with a 1.5 horsepower motor.

A heavy duty cast iron fence of 22 7/8 inches. While the table is 28 1/2 inches. Usually, the length of stock you can joint is twice the length of the table. However, you can only joint up to 5 inches long without extra support with this machine. Which is actually ideal for small-scale home, garage, or woodshop owners both hobbyists and professionals alike.

On the other hand, it’s able to handle the densest hardwoods. It can be used for small to medium crafts and furniture giving accurate wood jointing.

Weighing in at 76 pounds, heavy enough to help woodworkers create masterpieces easier and with more precision while also being light enough to move it around.

Pros:

- Capable of cutting up to 6-inch width with a powerful 10,000 RPM cutter head.

- utting depth of 1/8 inch which is achieved with a rapid rate of 20,000 cuts per minute.

- Has a simple fence adjustment system with stops at 90 degrees and 45 degrees in and out.

- A hand wheel which allows you to adjust the infeed table height.

- The cutter head is equipped with a jackscrew arrangement which makes it easy to arrange and replace the blades. In addition, a pair of push blocks that let you move your wood boards safely.

Cons:

- The fence demands some time to get squared and aligned.

- Although there’s a built-in dust blower, it is advised to hook up a shop vac to the dust collection port or you will be cleaning dust for a long time.

Best Woodworking Jointer Comparison Table

| Feature/Product | Powermatic 54HH | Cutech 40160H-CT | JET JJ-6CSDX | Porter Cable PC160JT | Powermatic 60HH | Delta 37-071 |

|---|---|---|---|---|---|---|

| Horsepower | 1 HP | 1 HP | 1 HP | 1.4 HP | 2 HP | 1.5 HP |

| Voltage | 115/230 V. | 120 V. | 115/230 V. | 120 V. | 230 V. | 120 V. |

| Amperage | 13/6.5 A. | 10 A. | 13/6.5 A. | 10 A. | 9 A. | 12 A. |

| Fence Tilt | +/- 45° | 90° - 135° | +/- 45° | 0 - 45° | +/- 45° | 0 - 45° |

| Positive Stops | 45°, 90°, -45° | N/A | 45°, 90°, -45° | N/A | 45°, 90°, -45° | 45°, 90°, 135° |

| Dust Port | 4 In. | 2.5 In. | 4 In. | 2.5 In. | 4 In. | 2.25 In. |

| Weight | 328 lb. | 40 lb. | 256 lb. | 40 lb. | 518 lb. | 76 lb. |

| Dimensions (LxWxH) | 66 x 24 x 37.5 In. | 32 x 12.25 x 11 In. | 56 x 31.25 x 37.5 In. | 32 x 12.5 x 11.25 In. | 73 x 25 x 46 In. | 28.5 x 17 x 12.25 In. |

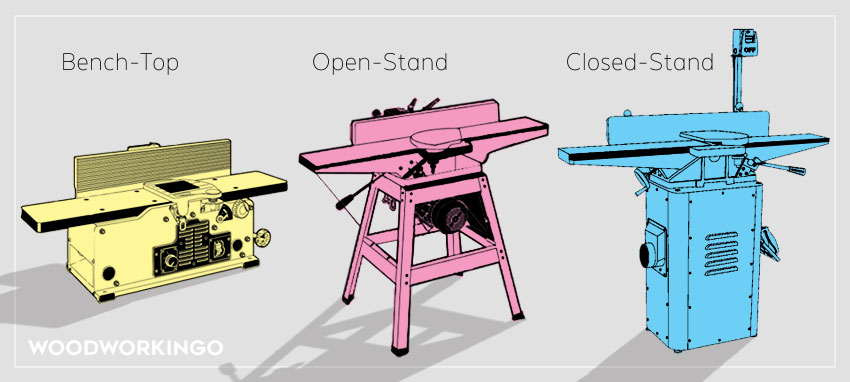

Types of Wood Jointers

Before we can explain how to choose the best jointer for woodworking, first let’s explain the different types of jointers available in the market. In fact, there are 4 different types of wood jointers. Each different type of jointer is made to suit the needs of the woodworker and the projects involved.

-

Benchtop Jointers

A benchtop jointer is a table top jointer that sits on your workbench. It is designed to not take up much space and is generally cheaper than most other jointers. This type of wood jointer is ideal for those who do not have much space. You just need to make sure you still have enough room on each side to be able to feed the wood into the jointer and get it out from the other side easily. Since the benchtop jointers are usually more affordable, then consider purchasing an open stand for your jointer later down the road for your workshop. You will find plenty of choices for this type in our benchtop jointer reviews.

-

Closed Stand Jointers

A closed stand jointer is generally the best option for most woodworkers. They help to keep the dust off of the machine and out of the motor which in turn helps extend the life of the jointer. The closed stand means that the stand that is underneath of the jointer is closed in. This is ideal for a workshop to help keep it clean and to help make your jointer last longer.

-

Open Stand Jointers

An open stand jointer is basically just the framing of the stand and everything else is hollow. These stands tend to be cheaper and can even be bought separately. However, they do allow dust and debris to get around the workshop and can allow for a mess to build. These stands can often be purchased later and you can convert your benchtop jointer to an open stand jointer whenever you need.

-

Combination Jointers

A jointer combination is actually a multi-tool. It is a jointer and a planer. When you get more involved with your projects you will find that you need to plane the wood after you run it through the jointer. Although a combination jointer can be a little expensive, it can maximize your workspace and combine two tools into one. A planer is very essential in getting the depth of the wood down to the size you need for your project.

How to Choose the Best Jointer?

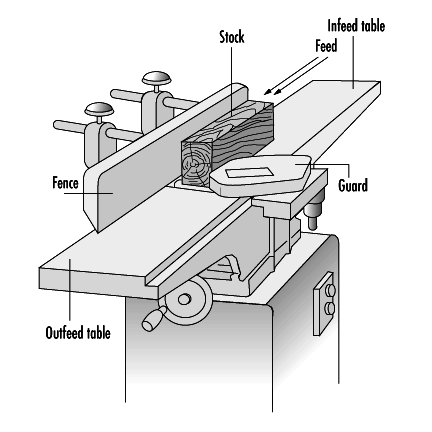

There are so many types of wood jointers available. Each jointer comes with a variety of different options depending on what you are looking for. This includes width, depth, table size, motor power, blade count, how many cuts it can do per minute, dust collection, accessories, and more.

When you are first learning how to use a jointer, you do not need the top of the line jointer. Start with something small but built well. This allows you some room to learn with it. As you get better, if the jointer you purchase is not keeping up with you, move on to a higher quality, a more expensive jointer.

6″ Jointers or 8″ Jointers or More

The bed width will determine how wide the wood can be in order to fit in the jointer. A 6-inch jointer will allow up to 6-inch wide piece of wood to go through. The same goes for an 8-inch jointer. Most projects require a 6-inch piece of wood. However, if you will be doing larger projects it is best to have an 8-inch jointer. If you need something to handle wider wood, then you would want a long bed jointer that can accommodate that.

Bed Length

The bed length limits the size of the wood you can mill with your jointer. Wood jointers can normally handle lumber twice the length of the table (bed), so you should also take into consideration the length of the table (bed). However, if your work rarely requires lengthier lumber then you can purchase a bed extension instead of paying much more for a jointer with a longer bed.

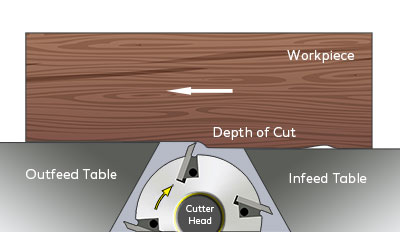

Cutting Depth

The cutting depth makes you decide how many times you need to put the wood through the jointer to make it completely straight. This is generally done at a half or three-quarters of an inch. Every time you put the wood through the jointer, it takes a little more warp out of it. In the end, you will have a perfectly straight piece of wood.

Cuts per Minute (CPM)

The cuts per minute are determined by the number of blades multiplied by the speed of the cutter head. For example, a 6000 RPM cutter head with 4 knives makes 24,000 cuts per minute. The more cuts per minute, the fewer times you will need to run the wood through your woodworking jointer. Bellow, we are discussing more details about the types of cutter heads.

The Fence

A fence is to help you make sure the wood is finished at the exact angle you need. The fence is just like a fence. It holds the wood in the correct place to make an angle using the jointer. Angling the fence is simplified when there are positive stops. This is particularly useful when you are trying to put two corners together and you need each piece to be cut at a 45-degree angle. Then you can be sure that the angles will match up when you place the two pieces of wood together.

The Motor

A general wood jointer will come with a standard 1 horsepower. The power derived from this should be plenty to even out any type of wood with no issues. Also, check the voltage and amperage rating for the unit. By multiplying the two values you will get the wattage rating for it. A motor with a high wattage rating at an affordable cost is a great choice.

The Weight

A jointer tends to weigh a lot so you do not want to get a jointer that you are going to have to move every time you want to use it unless it is on a stand that has wheels where you can roll it. If you buy a benchtop jointer and have to move it on and off the workbench when you want to use it. Then you are going to have a hard time and it is probably better to purchase a jointer that is on a stand or purchase a stand for your machine. Wood jointers tend to way over 200 pounds depending on what you purchase.

Dust Collection Ability

When you are straightening the wood with a jointer, it can lead to a lot of wood dust flying around. If your jointer has a dust collector on it, the dust will go straight through the vacuum hose. Most people set this hose up to a shop vac of some sort and when they turn on the shop vac, it helps to suck the dust out of the machine. This helps keep your area, workshop, and machine clean of dust and debris.

As you can see there are many types of power jointers and many options to choose with each one. Determining what your workspace allows is the first step in determining which wood jointer will work best for you. Then decide on how wide the wood of the majority of your projects is going to be in order to determine which width is best for you. Not to forget, the safety factors for each machine. Warranty is also very important especially that these machines are usually expensive so it’s an important factor to consider for your investment.

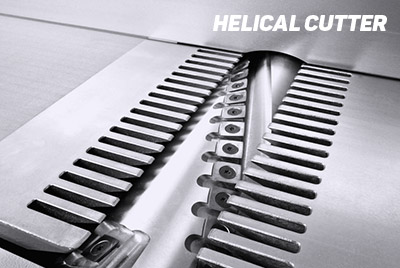

Conventional Knives vs. Helical Cutters for Jointers

Helical cutters are also called spiral cutters. Many of the jointers on the market today have conventional knives but you can also convert them to make these circles. However, it can be expensive to convert the jointers into a helical cutter. But is it actually worth doing? The short answer is yes. But first, let’s explain what a helical cutter actually is.

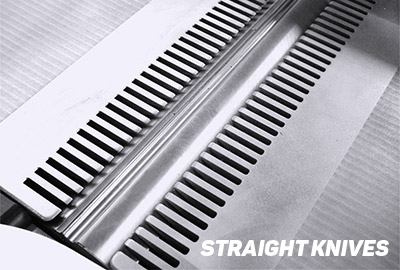

Jointers with Conventional Knives

Standard jointers have anywhere from two to four blades that rotate on a drum in a cylindrical manner. These types of blades are conventional or straight knives. This has always been an effective way of making the wood even. However, it can leave dents in the wood where the conventional blades don’t touch if they are not passed through enough or turned before passing through each time.

Jointers with Helical Cutters

The helical blade has anywhere from ten to forty blades and sometimes, even more, arranged in a helical or spiral pattern on the cutter head. The dimensions do not change on the cutter. However, with an increased number of blades, the indents in the wood when ran through the jointer decreases greatly. This is because the blade cuts a small amount of wood off when passing through rather than a long strip like with the traditional straight blades. This can be beneficial even when you are passing the wood through against the grain.

So now that you understand what a helical cutter head does, we can explain why it would be a good financial investment.

What are the Advantages?

Blade replacement plays a key role in the financial investment to convert your jointer to a helical cutter. When using a conventional blade, it can become damaged. If your blade is a double-sided blade, you can turn the blade one time to utilize it the most. However, after the one turn, that blade is no longer useful and you will need to replace it. With a helical blade, you can purchase four-sided blades. This means that you can turn the blade four different times before it is no longer useful.

Another beneficial reason is damaged blades. Blades can become nicked when it comes in contact with a nail or a staple. A conventional blade can still be turned but it ruins that entire side of the blade. However, with a helical blade, they are made of inserts. All you will need is to replace that one insert and you can move on. The rest of your inserts are still useful. This allows your helical cutter to last much longer than a conventional blade.

There are some reasons why a helical cutter is better than a conventional blade that is not financial related reasons. Helical cutters can be quieter than conventional blades. They also make the shavings from the wood much smaller which helps with the dust collection. When using a conventional blade, they tend to make long shavings and can get caught in the pipe or hose of your dust collector.

What are the Downfalls?

A helical cutter can’t be perfect right? There is always a downside to even the best woodworking jointer. A helical cutter requires more power which can put a strain on the motor. Machines that already come with a helical cutter can obviously handle this already. However, when you convert your jointer, the motor usually cannot handle this change. The manufacturers have thought of this. So, when you buy the conversion kit, it comes with a new gear set that will increase the torque and lower the RPMs. It won’t be quite the same as if you were to have bought a jointer with a helical cutter but it won’t be much different.

So which do you choose? What is better? It really depends on you. If you are going to purchase a jointer and the helical cutter only has 10 to 12 blades, it is not much different than a jointer with conventional cutters. Therefore, to find the best jointer for the money, it may not be financially supportive to pay more money for the jointer with helical cutters. If you have the extra funds and can manage to purchase a jointer with a higher amount of blades on the helical cutter, then that is the obvious choice. In the long run, the machine will pay for itself in the difference in the number of blades or inserts that will require replacement after use. Helical cutters are by far the best choice, especially for the experienced woodworker. It all comes down to making a decision that works best for you and the projects you have in mind.

Everything you Need to Know About Benchtop Jointers

So you are getting better at your woodworking skills and are ready to increase your knowledge and experience by adding new tools and learning how to use them. When you purchase your lumber from the lumber store, you tend to get wood that is not flat or straight. Many times it is twisted, warped, or cupped and it is not useful for your woodworking projects. This is where a jointer comes in.

A wood jointer is a tool that utilizes a flat blade to level out a board. You place the wood, warped side down, on the blade side of the wood jointer and push it through. When you pull it out of the other end of the wood jointer, it will be less warped. This process has to be repeated a few times in order to straighten out the wood depending on how warped or twisted it may be.

What Does a Jointer Do?

A wood jointer takes warped and twisted wood and straightens it out. It can also square an edge of the wood before you put it on the

What are the Benefits of Using a Jointer?

Many people find their wood jointers to be an essential tool in their workshop. Jointers can be used by anyone with little to no experience to an expert in the woodworking field. One benefit of a wood jointer is saving money. Often times, stores will have a discounted section for wood that has flaws such as being warped or twisted. If you look for these sections, you can purchase this wood cheaper and fix the flaws with your wood jointer. This could potentially save you hundreds of dollars depending on how big or small your project is. There are also lumber liquidators who sell mostly this type of wood. This may cost you some time but will definitely save you some cash.

Whether you do woodworking for a hobby or it is a part of your business, stocking up on wood is inevitable. This could be from a sale or a project that you never got to. Once the wood has sat for some time, it can become warped. This can be due to moisture in the air or the way it has been laying. There is no need to throw the wood out. This is where the wood jointer becomes a beneficial tool to have. You can straighten out the warps and even the twists and edges.

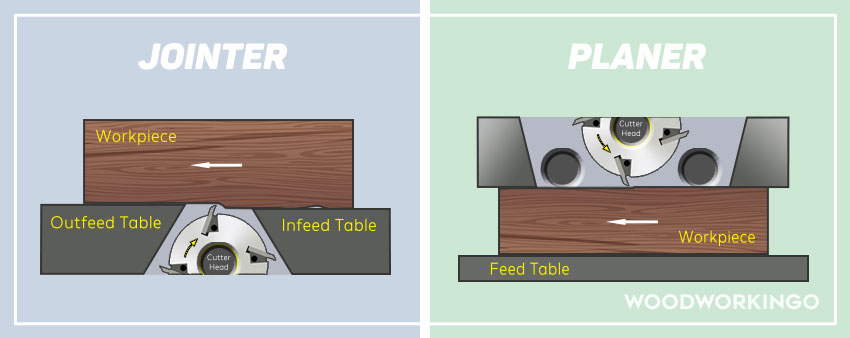

What is the Difference Between a Jointer & a Planer?

A jointer is a tool you can use to remove the twists and warps and make your board flat so that you can move on with your woodworking project. A planer is a tool that you can use to make your wood the desired thickness for your woodworking project. That is the difference between the two. The planing comes after the jointing.

When using a wood jointer, you would run the wood through the wood jointer on one side and then run it through the wood planer on the other side. By utilizing both of these tools, you cut down your time in getting the wood perfect for your project.

You may also be interested to check our in-depth comparison of the best benchtop planers or the best electric hand planers lists.

As you can see a wood jointer has a lot to offer and is an essential tool for woodworking. It benefits you by saving money and saving wood. It straightens out bent wood and fixes bends and twists in warped wood. The main difference between them is that a jointer does not reduce the width of the wood as a planer does. Jointers comes in a tabletop form or in a stand-alone form. Either way, you will want to make sure there is plenty of clearance on either side of your woodworking jointer so that you have plenty of room to put your wood into the jointer and plenty of room for it to come out of it.

Bottom Line

With the jointer reviews you found here, it can feel overwhelming. Just ensure that you are choosing the best power jointer for your purpose by going over the key features and options. A dust collector is optional but it is a good accessory to have. Consider the different kinds of blades offered to find the best wood jointer that is most suitable for you. If you are in a small space, consider the best benchtop jointer that has a good fence, made from sturdy materials, and does not move from all the vibrations. Make sure you are getting a woodworking jointer that is not confusing to set up and use. Compare the key features to help you determine which is the best jointer for your projects and needs.